Challenge

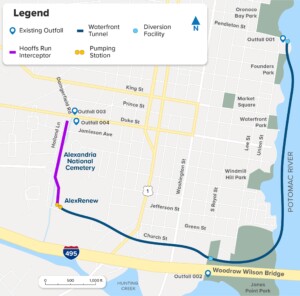

Like many older cities in the United States, the city of Alexandria, VA, is served by combined sewers, which discharge excess flows into local waterways via combined sewer outfalls (CSO). In April 2017, the Virginia General Assembly passed a new law requiring the remediation of CSOs that discharge combined sewage into the Potomac River and its tributaries. In response to the law, Alexandria Renew Enterprises (AlexRenew or owner), with support from the City of Alexandria, developed the RiverRenew Program to meet strict regulatory requirements and an aggressive timeline.

The RiverRenew Program is the largest infrastructure initiative in the history of Alexandria with an estimated capital cost of $615 million. The RiverRenew Program encompasses the RiverRenew Tunnel System project, a storage and conveyance tunnel system, as well as three other wastewater projects that paved the way for the tunnel system project.

The schedule stipulated by the 2017 CSO law requires the tunnel system to be operational by July 1, 2025. AlexRenew worked expeditiously on parallel tracks to advance conceptual-level designs, comply with the National Environmental Policy Act (NEPA) through the development of an environmental assessment with the National Park Service, and acquire the necessary permits and agreements needed to build the tunnel system. In addition, AlexRenew simultaneously developed and implemented a two-step procurement involving a request for qualifications (RFQ) phase and request for proposals (RFP) phase to hire a design-builder.

Approach

The project consists of the following components:

- 2-mile-long, 12-foot-diameter storage and conveyance tunnel approximately

100- to 140-feet deep - 35- and 37-foot drop shafts

- 2,500-foot-long, 6-foot-diameter open-cut interceptor

- 20 mgd tunnel dewatering pumping station

- 180 mgd wet weather pumping station housed in 65-foot-diameter shaft

- 35-foot-diameter screening shaft

- 4-story pumping station superstructure

AlexRenew hired Brown and Caldwell (BC) as its owner advisor (OA) to provide delivery method selection, risk analysis, design criteria development, procurement services, significant stakeholder engagement, and public outreach. After a thorough evaluation of various delivery methods, AlexRenew selected fixed-price design-build (FPDB) to implement the project, which had a proven precedent for underground work. FPDB provided the owner with schedule and price certainty needed to meet the legislative mandate and corresponding July 1, 2025, deadline.

Early market sounding and industry engagement encouraged competition with eight design-build teams submitting a statement of qualifications (SOQ). AlexRenew then conducted a fair and transparent evaluation to shortlist three teams to receive the RFP. Collaborative one-on-one proprietary meetings with the short-listed teams and clear evaluation criteria in the RFP led AlexRenew to select a design-build joint venture team based on a best-value 50/50 technical/price weighting. The joint venture team includes Traylor-Shea as the prime design-builder with Jacobs as lead designer.

The design-build team received notice to proceed on December 1, 2020, and worked in conjunction to develop the final designs that were coordinated for construction sequencing. The design included a tunnel dewatering and wet weather pumping station and an associated superstructure, a 12-foot-diameter conveyance and storage tunnel, and a 6-foot-diameter interceptor sewer. The final design was developed to meet a compressed schedule, through close collaboration with AlexRenew and the OA team, while mitigating potential impacts to stakeholders and the community to the greatest extent possible.

The resident engineering (RE) team, supported by Stantec, is managing construction at the four construction staging areas (CSA). The CSAs are defined both functionally and geographically. For example, the wet weather pump station and waterfront tunnel activities are located within a CSA at AlexRenew’s Water Resource and Recovery Facility (WRRF), while the other CSAs are located at sites external to the WRRF in the vicinity of the CSOs. Although the work at each CSA varies, the sequencing of activities at each CSA is coordinated to deliver the tunnel system before the legislative deadline. The RE team facilitates coordination between the design-builder and OA during the design and construction phase, while considering environmental and community impacts and mitigations, specific to each individual CSA. The RE team’s understanding of the contract requirements provides value to the owner and the design-builder through constructability reviews and managing construction permit review and approvals required by the City of Alexandria.

As a significant milestone, celebrated by the project team and the Alexandria community, a new 380-ton, 14-foot-8-inch-tall tunnel boring machine (TBM) named Hazel was unveiled by AlexRenew in the summer of 2022. The TBM carries the namesake of Hazel Johnson, one of America’s leading women pioneers for environmental justice. Making its way from Schwanau, Germany, to Alexandria, a welcome reception was held to celebrate Hazel’s arrival, with over 100 attendees, including Alexandria’s mayor, Justin Wilson.

Results

Public Outreach and Stakeholder Engagement. Since AlexRenew serves an active and engaged community, the owner tasked the project team with early and continuous outreach to inform and engage impacted neighborhoods and rate payers to gather their input. The project team collaborated with AlexRenew to develop and implement a comprehensive stakeholder outreach and engagement plan for the RiverRenew Program. One example includes the community listening sessions held to obtain community input and feedback on project alternatives, which helped inform the selected alternative. Another example of community engagement was the formation of a stakeholder advisory group (SAG). The SAG advocates for the project, communicates progress to the community, gathers community input, and helps the project team mitigate potential construction issues.

Industry Outreach. The outreach efforts also extended to the tunneling industry to generate contractor interest and provide market-based validation of project requirements. Since there were multiple ways to package the large tunnel and pumping station system, the industry outreach campaign gave AlexRenew confidence that packaging a large-diameter tunnel with a pumping station was acceptable to the industry. Through industry feedback, AlexRenew determined that combining all project components into a single contract provided the most schedule certainty to meet the legislative mandate. Using FPDB delivery also enhanced innovation on the part of the design-builder while maintaining the design intent and hydraulic performance required by the CSO law.

Sustainability. The development of the project through planning and design phases focused on mitigating potential impacts to the community and providing permanent public improvements where possible. This community-based approach was emphasized by the requirement included in the contract for the design-build team to achieve Silver levels of certification in both LEED and Envision. One aspect of the sustainable design is the requirement to provide a public promenade as part of the restoration efforts at one of the CSAs. The promenade will benefit the community by providing additional connectivity and new access to the Alexandria waterfront along the Potomac River.

Maintenance of Plant Operations. The scale of the construction activities at AlexRenew’s WRRF, alongside the normal plant operations and deliveries at AlexRenew’s constrained campus, requires close coordination between the design-builder and the owner to maintain plant operations. A plant impact request (PIR) workflow was established as the mechanism for the design-builder to identify upcoming logistical needs and potential impacts. Within the PIR submittal, the design-builder provides its mitigation approach for review and approval by AlexRenew’s staff.

Other WCDA member involved: Kokosing Industrial (construction subcontractor responsible for near surface structures and pumping station superstructure)

“As the largest infrastructure project in Alexandria’s history, RiverRenew will benefit and protect our waterways, our community, and our future. Our dedicated project team has made significant progress on the RiverRenew Program and continues to advance to meet the mandate. The design-build delivery method has allowed us to develop a collaborative culture and ensure success of the program to date.”

—Justin Carl, AlexRenew General Manager