Brushless motors have different methods of controlling current flow depending on the drive system. In addition, to control the rotation speed and generated torque, it is necessary to control the amount of the motor current. Here, we will explain the PWM method for controlling the motor current.

| Current Control Method |

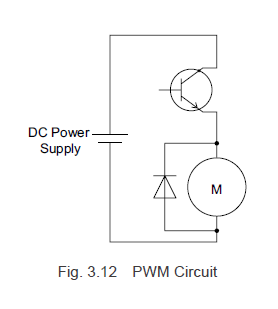

An electrical control system called PWM (Pulse Width Modulation) is used as a control method for the voltage that is applied to the motor windings. PWM control is a method of controlling the output voltage by repeatedly turning the switching element in the circuit ON and OFF and creating a pulse-shaped voltage.

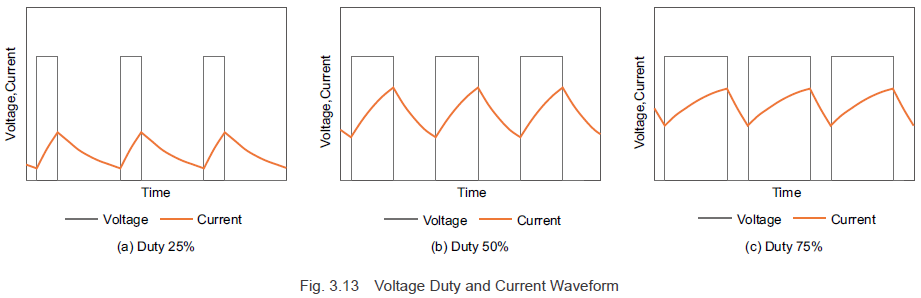

Fig 3.12 shows a PWM control circuit model for a DC motor. Fig. 3.13 shows the voltage waveform and current waveform when the pulse width changes (modulation) during the ON phase. Modulating the pulse width and changing the duty ratio for the ON/OFF switching element controls the average voltage.

At this point, the inductance causes the current to lag behind the increased voltage, and when the application of voltage is removed, it gradually decreases.

3.31 Modulation Method

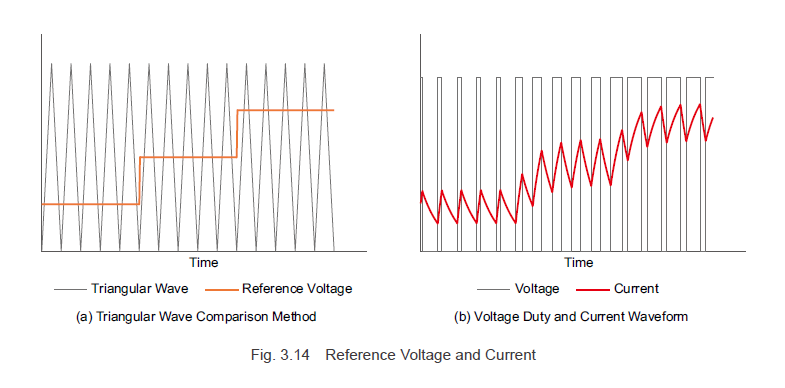

Let us explain the modulation method for PWM control, which was explained in Fig. 3.13. The PWM control duty ratio is decided by comparing the standard triangular wave signal and reference voltage and turning the switching element ON if that the triangular wave signal voltage is lower than the reference voltage, or OFF if it is higher. In order to increase the motor current, the reference voltage needs to be increased. This means that the switching element duty ratio gets larger, and because the average voltage increases, the motor current increases. If the reference voltage is lowered, the switching element duty ratio gets smaller, and because the average voltage decreases, the motor current decreases.

Brushless motors with a square wave drive system adjust the motor current using PWM control for the switching element that excites the motor windings, and they control the rotation speed and generated torque.

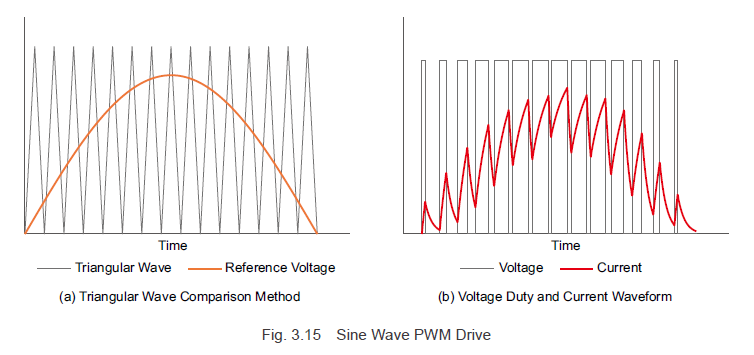

3.3.2 Sine Wave Drive System Modulation Method

Let us explain the modulation method for a sine wave drive system, which was explained in Fig. 3.10. If the reference voltage is made into a sinusoidal shape, the switching element duty ratio continuously modulates and a sinusoidal current can flow. In other words, with PWM control, the reference voltage waveform and the current waveform assume the same form. (The reference voltage for the waveform one wishes to output is called the modulating signal.) Brushless motors with a sine wave drive system perform PWM control just like with a square wave drive system, but the reference voltage creation method is different.

The sine wave motor current from Formula (3.6) is a function of the current waveform value im and the rotor angle Θ. By creating a modulating signal from the rotor angle information and the current command value, the current that flows to the motor windings is adjusted and the rotation speed and generated torque are controlled.

Thus, to perform sine wave driving in brushless motors, it's important for the driver to precisely detect the rotor magnet angles and therefore "close the loop". This can be done either through hall-effect sensors or encoders. Oriental Motor uses both to satisfy different speed accuracy requirements.

Learn more about Oriental Motor's

Subscribe (top right corner) to receive monthly updates!